空气弹簧是汽车空气悬架系统的和重要组成部分,它利用空气的压缩弹性进行工作,具有缓冲、减振和承载重量等功能。空气弹簧具有优良的弹性特性,与普通钢制弹簧相比有许多优点,因而其应用范围十分广泛。将空气弹簧用于汽车悬架系统可大大提高汽车的行驶平顺性和舒适性。

1934年,费尔斯通公司研制出膜片式空气弹簧并首先在美国通用客车上试应用成功。20世纪50年代中期,空气弹簧产品经过多年的研发和试验,有关技术逐步成熟,装有空气悬架的客车开始在美国、德国得到大批量推广应用。20世纪80年代以来,世界上主要的发达国家为了减少车辆对道路的破坏和增加车辆的舒适性,在客车上几乎全部使用了空气弹簧,重型商用车上的使用率也超过了80%。

空气弹簧的种类

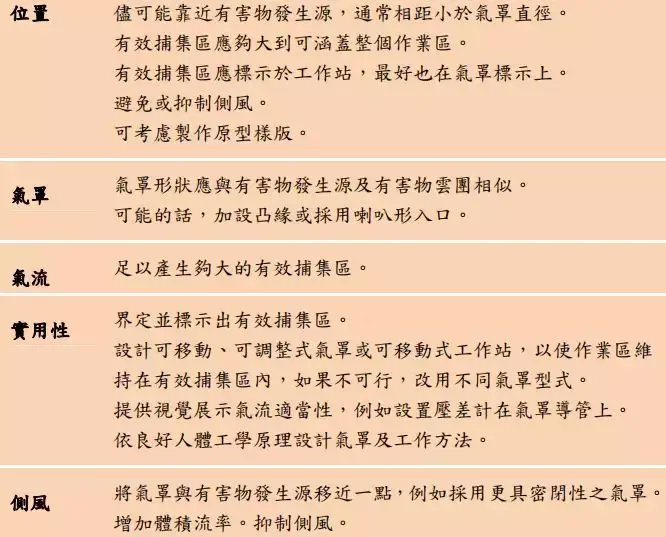

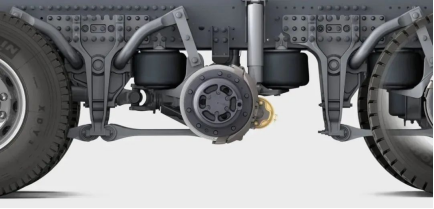

空气弹簧由橡胶气囊、上盖板、底座、辅助气室,夹紧环和缓冲块等组成。根据橡胶气囊工作时变形式的不同,空气弹簧的结构形式主要分为膜式空气弹簧、囊式空气弹簧和混合式空气弹簧3种。膜式空气弹簧是圆柱形结构,根据橡胶气囊止口与接口的连接方式,膜式空气弹簧又分为约束膜式和自由膜式。约束膜式空气弹簧一般用螺栓夹紧密封,自由膜式空气弹簧则采用橡胶气囊的压力自封。囊式空气弹簧的外形结构有些像灯笼,有单曲、双曲或多曲囊式空气弹簧。早期的商用车上主要使用双曲囊和三曲囊式空气弹簧。近期膜式空气弹簧的用量逐步增加,是因为膜式空气弹簧具有行驶平顺性好和行程大的优点。

空气弹簧的结构

空气弹簧是利用夹有帘线的橡胶气囊内压缩空气的反力作为弹性恢复力的一种弹性元件。它由橡胶气囊、上盖板、底座等部件组成,其内部充满压缩气体。其中橡胶气囊是空气弹簧的重要部件,其橡胶气囊由内外覆层(内橡胶层、外橡胶层)、帘线层和钢丝圈硫化而成。

①内外覆层(内橡胶层、外橡胶层)

空气弹簧橡胶气囊壁的内外覆层由贵重的弹性材料制成,具有特别好的动力学特性,在一定的限度内耐温、耐气候侵蚀和耐油。内覆层主要是用以密封,因此采用气密性和耐油性较好的橡胶。

②帘线层

空气弹簧的载荷主要由帘线层承受,帘线的材质对空气弹簧的耐久性和耐压性起决定性的作用。一般由两层支撑体交叉排列的帘线构成。在用于轨道车辆的空气弹簧中,也采用4层和6层交叉排列的帘线。这些帘线特别耐弯曲,通过优化设计角度,抗破裂性能好、强度大。

③钢丝圈

钢丝圈被硫化进空气弹簧胶囊两个各有一个凸缘的开口端内,凸缘让其能类似于无内胎轮胎装到柱塞和板之类的固定零件上,或借助于折边和螺栓再张紧到这些零件上,并且不漏气。根据空气弹簧的种类,钢丝圈保持空气弹簧胶囊能长期固定在圆锥状密封面或一个特殊形状的固定件上。

空气弹簧装置系统的优点

①空气弹簧能够大幅度提高车辆悬挂系统的静挠度,以降低车体的振动频率。

②与钢弹簧相比,空气弹簧具有非线性特性,可以根据车辆振动性能的需要,使钢弹簧具有比较理想的弹性特性曲线。

③空气弹簧的刚度随载荷变化而变化,保持空、重车时车体的振动频率几乎相等,使空车和重车状态的运行平稳性一致。

④空气弹簧用高度控制阀控制时,使车体在不同静载荷下,保持车辆地板面距钢轨面的高度基本不变。

⑤空气弹簧可以同时承受三维方向的载荷,可代替摇动台装置,简化结构,减轻自重。

⑥在空气弹簧本体和附加空气室之间装设有适宜的节流孔,可代替垂直安装的液压减振器。

⑦空气弹簧具有良好的吸收高频振动和隔声性能。

A detailed introduction to air springs

The air spring is an important part of the air suspension system of the automobile. It uses the compression elasticity of the air to work, and has the functions of buffering, damping and bearing weight. Air springs have excellent elastic properties and have many advantages compared with ordinary steel springs, so they have a wide range of applications. The use of air springs in automobile suspension systems can greatly improve the ride comfort and comfort of automobiles.

In 1934, Firestone Company developed a diaphragm air spring, which was first successfully used in a test on a GM bus in the United States.In the mid-1950s, after years of research and development and testing, air spring products gradually matured, and passenger cars equipped with air suspension began to be popularized and applied in large quantities in the United States and Germany. Since the 1980s, in order to reduce the damage to the road and increase the comfort of vehicles, the major developed countries in the world have used air springs in almost all passenger cars, and the utilization rate on heavy commercial vehicles has also exceeded 80%.

Types of air springs

The air spring is composed of a rubber air bag, an upper cover plate, a base, an auxiliary air chamber, a clamping ring and a buffer block。 According to the different working time-varying forms of the rubber airbag, the structural forms of the air spring are mainly divided into three types: membrane air spring, bladder air spring and hybrid air spring。 The membrane air spring is a cylindrical structure。 According to the connection method between the rubber airbag stop and the interface, the membrane air spring is divided into a constrained membrane type and a free membrane type。

The constrained membrane air spring is generally clamped and sealed with bolts, while the free membrane air spring is self-sealed by the pressure of the rubber airbag。 The shape and structure of the bladder air spring is somewhat like a lantern, and there are single, hyperbolic or multi-curve bladder air springs。 Early commercial vehicles mainly used double-curved and triple-curved air springs。 Recently, the amount of membrane air springs has gradually increased because the membrane air springs have the advantages of good ride comfort and large stroke。

The structure of the air spring

The air spring is an elastic element that uses the reaction force of the compressed air in the rubber airbag with the cord as the elastic restoring force.It consists of a rubber airbag, an upper cover, a base and other components, and its interior is filled with compressed gas. Among them, the rubber air bag is an important part of the air spring, and the rubber air bag is vulcanized from the inner and outer covering layers (inner rubber layer, outer rubber layer), cord layer and steel ring.

①Inner and outer cover (inner rubber layer, outer rubber layer)

The inner and outer cladding of the air spring rubber airbag wall is made of precious elastic material, which has particularly good dynamic properties and is resistant to temperature, weathering and oil within certain limits. The inner cover is mainly used for sealing, so rubber with better air tightness and oil resistance is used.

②Cord layer

The load of the air spring is mainly borne by the cord layer, and the material of the cord plays a decisive role in the durability and pressure resistance of the air spring. It is generally composed of two layers of support cords arranged in a cross. In air springs for rail vehicles, 4-layer and 6-layer interdigitated cords are also used. These cords are particularly resistant to bending and, by optimizing the design angle, have good resistance to breakage and high strength.

③ Bead ring

The bead ring is cured into the two open ends of the air spring bladder with one flange each, the flanges allow it to be mounted on fixed parts such as plungers and plates similar to tubeless tires, or by means of flanges and bolts ,and without leakingair. Depending on the type of air spring, the bead ring keeps the air spring bladderpermanently fixed to the conical sealing surface or to a specially shaped fixture.

Advantages of the air spring system

①The air spring can greatly improve the static deflection of the vehicle suspension system to reduce the vibration frequency of the vehicle body.

②Compared with steel springs, air springs have nonlinear characteristics, which can make steel springs have an ideal elastic characteristic curve according to the needs of vehicle vibration performance.

③The stiffness of the air spring changes with the load, and the vibration frequency of the car body is almost equal when the vehicle is empty and heavy, so that the running stability of the empty and heavy vehicles is consistent.

④When the air spring is controlled by the height control valve, the height of the vehicle floor from the rail surface is kept basically unchanged under different static loads of the vehicle body.

⑤The air spring can bear the load in three-dimensional direction at the same time, which can replace the shaking table device, simplify the structure and reduce the self-weight.

⑥A suitable orifice is installed between the air spring body and the additional air chamber, which can replace the vertically installed hydraulic shock absorber.

⑦The air spring has good absorption of high frequency vibration and sound insulation.

限 时 特 惠: 本站每日持续更新海量各大内部创业教程,一年会员只需98元,全站资源免费下载 点击查看详情

站 长 微 信: lzxmw777